The View from the hill 29th March 2023

This year’s calving has romped on at a great pace. The 21 heifers all finished several weeks ago, and most are in the yards at Websley with their calves. The main herd started at the beginning of March and over the following 3 weeks popped them out at a good rate, we are down to less than 10 now, the busiest day saw 8 born, and yes it was a Saturday, during the 6 Nations rugby tournament. Doug and Brendan had to sort and tag 10 calves on the one day, before they get muddled and we lose sight of who belonged to which cow. This little fellow demonstrates clearly why we decided to bring in a Hereford bull, Theo, as a change from 100% (black) Angus, irresistible with the white face, red body and fluttery eyelashes, we didn’t really need to write the bull’s name on her tag, but it has become a habit, so that we avoid embarrassing partnerships 2 years down the line, when we bring new heifers into the herd. Our other bull, Mr Red, a recessive red Angus, has produced some lovely coloured calves too, like the twins I mentioned last month, bringing even more visual variety into the herd. It will take a cleverer person than I though, to properly explain the genetics of the recessive red Angus, suffice to say he will throw calves of different colours depending on the colour genes carried by the mother.

One day last week we had to turf out one penful of cows into a nearby paddock so we could use their pen for sorting out the youngstock, who have been outdoors all winter, but have run out of grub. They have worked their way across all the cover crop fields, munching off the mixed species covers at approx 1.2 hectares per day, this at least means that we can in theory get on and sow the barley that will follow, except that the unusually wet March we are experiencing has prevented any tractor action in the fields for the last 3 weeks. 140mm so far, the average for March being 74mm. The younger ones were heading one way, to a field where we can feed them silage, and the older ones were heading across the farm towards the river meadows, where there is some grass. While the cows were outside, enjoying a thin bite of grass on a brisk day, two of them decided to calve, just in the two hours they were outside.

The cows get mucked out a couple of times during the winter, so that they don’t end up jumping over the gates or banging their heads on the roof of their shed. The muck gets hauled out to the fields where it will be composted with woodchip, anaerobic digestate, and maybe some green trimmings, before spreading in the autumn. It can be tricky juggling the handler if we have muck to move, and grain lorries to load, you can’t just drive it from the cow shed, covered in muck, to the grain store, it takes at least half an hour to wash it thoroughly, and then the tyres if still wet, will stick to grain, carry it outside and spread it all over the yard. We always try to avoid mucking out when lorries are due, but some of the grain merchants can be a bit ‘short notice’ with their collections, or perhaps it is the haulier, one can never be quite certain. One unfortunate driver had to wait rather too long the other day after a misunderstanding with his boss. We had cows temporarily outside, making a field muddy, and the clock ticking for getting the mucking out finished before dark, new straw bedding needed to be spread before the handler could be released, for washing then loading, with wet tyres anyway.

The spring barley is making an appearance this week, having been sown in the first few days of March the cold and wet has not encouraged it to emerge in a hurry. What it would like more than anything now is some warm sunshine and drier days so it can get on and grow away, and keep ahead of weeds and disease.

The 22/23 winter hedge planting campaign has at last drawn to a close, our target was 1,700 metres of new hedge, plus a quantity of gapping up where we’ve coppiced off some old and gappy hedge under our Stewardship scheme. With the aid of a team of very keen helpers from Durweston, and others from Bristol, we’ve managed to plant around 12,000 plants when the weather has allowed, over the last three months. Most of it now needs fencing in to keep cattle and marauding deer out, and this will keep Gary and Brendan busy in every spare moment when crops and cattle allow, for several weeks. It is great to see that some of the earlier planted whips are already leafing up or even flowering, the ‘pussy willow’ catkins of the Goat Willow have looked good but are already past their best now, as the leaves appear. The cat paw like catkins indicate a male plant, and it is to be hoped that we also planted some female ones, so that fertilisation and fruiting may occur. The female flowers are less showy, but offer plenty of nectar to attracts insects like bumblebees, with luck bearing pollen on their bodies, in order to successfully pollinate.

Other early flowering species which are already providing plenty of pollen and nectar for the season’s early emerging insect population include Gorse and Dandelion, which provide food for a longer season than most other flowering plants. We’ve also got Lesser Celandine just showing its face, in a beautiful clump around a tree in the paddock across the road. This photo is from last year, on 26th March. We are going to be several days later this year.

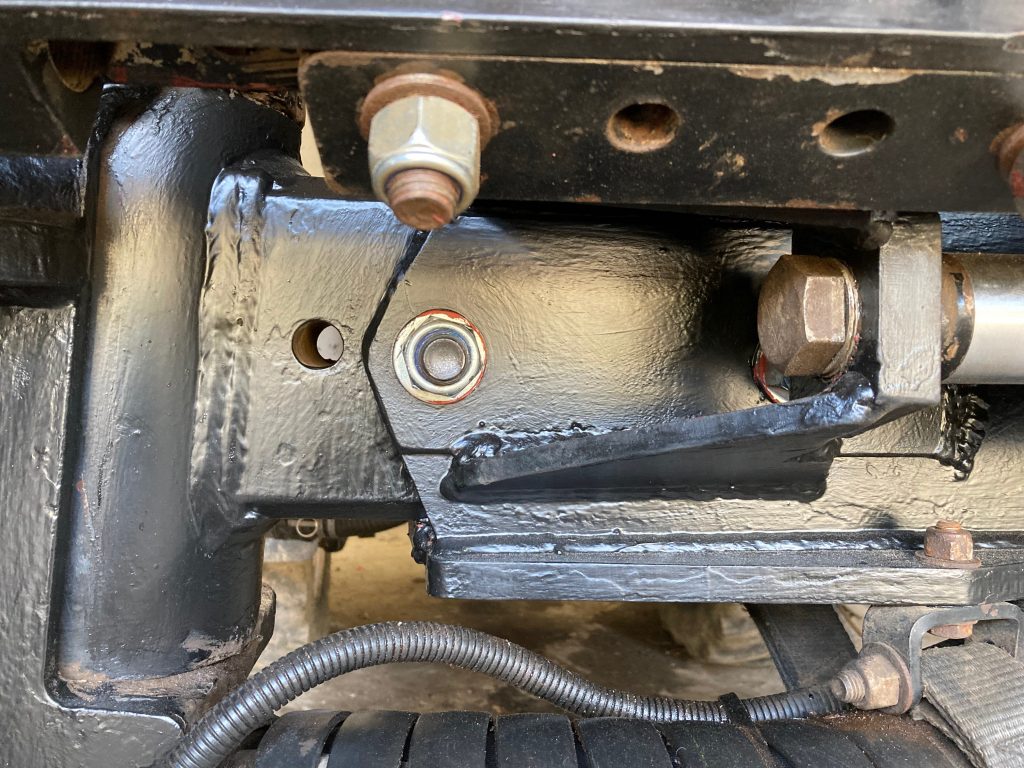

A bit of skilled engineering was called for last week, so a call went out to Drew, who kindly came along to help, as always endlessly resourceful and steady of hand. The problem was the rear axle of our Knight self-propelled sprayer. For several years it has been intermittently breaking the bolts that hold the sliding sections of the adjustable axle together. All the weight of the machine seemed to be riding on 4 bolts, as the machine aged (it is now 10 years old), what was once a snug fit had stretched and worn, so the bolts took all the strain. A short term bodge had involved inserting some shims between the inner and outer axle sections, which prolonged the life of the bolts, except the one which had rusted itself in solid. The effect of the shims though had been to open a crack in a weld on the outer section, so the bullet had to be bitten. Apologies for a bit of in-depth engineering talk, there could be at least one reader who will be paying attention in Essex.

A fantastic new tool which Drew brought along, that we hadn’t seen here before was an annular holecutter that will fit into an ordinary drill chuck on a portable drill. We are familiar with broach bits as used in a Mag drill, but had not seen them in a form that can be used in a portable. As engineering minded folks will know, anything larger than 12mm conventional twist bit in a portable drill is a pretty unwieldy thing, and it is very easy to blunt the outside edges, the area that does the most important cutting when drilling a hole. Whereas the multipoint cutter remains sharp for ages, and can be safely used up to 25mm or beyond if used carefully, which of course is where Drew comes in. At £40 a pop, these bits must be handled with respect.

The problem we had was the rusted-in bolt, 12.9 hardness and 20mm diameter, it was in an awkward position behind a bracket that the steering ram fixes to, which gave no straight aim for a hit to bash it out, or to drill out in one go. Until we removed the first 10mm of the bolt we could not remove the inner axle to then drill out the rest. Steady-hand Drew managed to cut the bolt head off at an angle to allow him to then drill out the first 10mm, freeing the axle to be pulled out. Then the rest of the bolt could be drilled out, a good eye and a steady hand being required again to drill the bolt itself and not the surrounding casting.

Once this was done, some cleaning up, fabrication of strengthening plates and welding them into place could proceed. Repeated on both sides, back and front, this repair has hopefully ensured safe and reliable service for a good while. Brendan gave the whole area a thorough wire-brushing, red oxide primer and top coat finished the job.

And Finally…….

Busy lambing here, George, but great stuff as usual. Your enthusiasm almost made the engineering details bearable!!

Very interesting drill bit, I followed all that with interest of course, what an absolute devil of a job, I would have called in an expert too – sometimes you jsut have to admit that you can’t manage everything and that particular job needed doing very properly.

8 calves in a day is quite a project for a beef herd, the older cows can be very adept at ‘stealing’ a calf from the younger ones and then being very confused when they have their own a day or two later and then the younger cow won’t take the original back as every time she has gone near it an old dragon has buffetted her away. You never have enough calving pens.

Love the sign, attributed to Therese Coffey, she truly is the most inept and unfit Minister I have ever come across! Hope all is well with you and the team at Durweston, looks like a very fine bit of hedge planting!

I’ve just read two newsletters, one from my MP and yours. One was infinitely better than the other!

Much more on drill bits please George. So many to choose from and who knew it? The Forstner bit would make an excellent Christmas 2023 feature. You need the 40mm version to make a tea light sized hole in a seasonal log. However, unlike your highly skilled freehand version above, you must use a pillar drill or equivalent to stand any chance of an accurate hole.

On the last picture I was trying to decide who was the older one….

Entertaining and instructive as always.

Good lecture at the parish room, recently, a fine balance between entertainment and instruction, with only minimal frighteners for the layman.

Keep up the pressure on th powers that be.

Jim